The following provides a summary of how a gasket roller might be used to fit rubber window gasket seal.

- Ensure that frame is clean and free of dirt, old adhesive, and anything that might interfere with the new gasket.

- Determine how much gasket is required by measuring the perimeter of the frame. Adding a little extra to the measurement can help ensure a tight fit at the corners.

- Cut the gasket to the determined length using straight, mitred, or diamond cuts at the corner, as your preference. Note that use of Gasket Shears will help you to achieve clean, accurate cuts.

- Starting at the top left of the frame, position the gasket over its groove, and push the end firmly, and fully into the corner.

- Feed the gasket along the top, applying light pressure with the gasket roller as you go.

- Once at the end, cut the gasket to length. A little extra length will compress into place for a better seal.

- Continue clockwise around the frame, repeating the position, push, feed and roll procedure with each side.

- Once the gasket is seated correctly around the frame, increase pressure with the roller to ensure secure fit into the groove. Avoid pressing too hard, as this can stretch and damage the gasket.

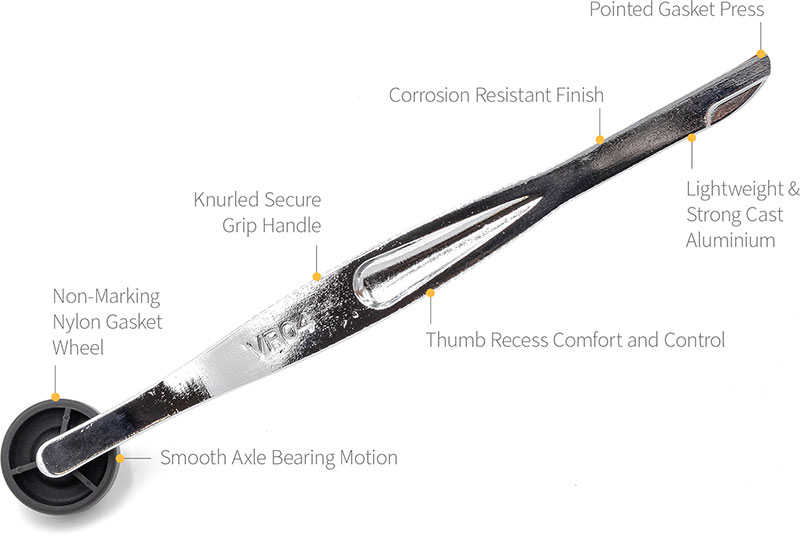

- Pay attention to corners, using the pointed gasket-press end to ensure a sound seal where the roller can't reach.

- Inspect the perimeter for gaps and loose areas, re-rolling them until they fit securely.

Following these steps should help you achieve a snug, durable fit for your window gasket seal.

Our uPVC window seal gasket roller can be used with a wide variety of window and door gaskets, and is packed with features to help you achieve secure seals with ease - without the risk of over stretching.