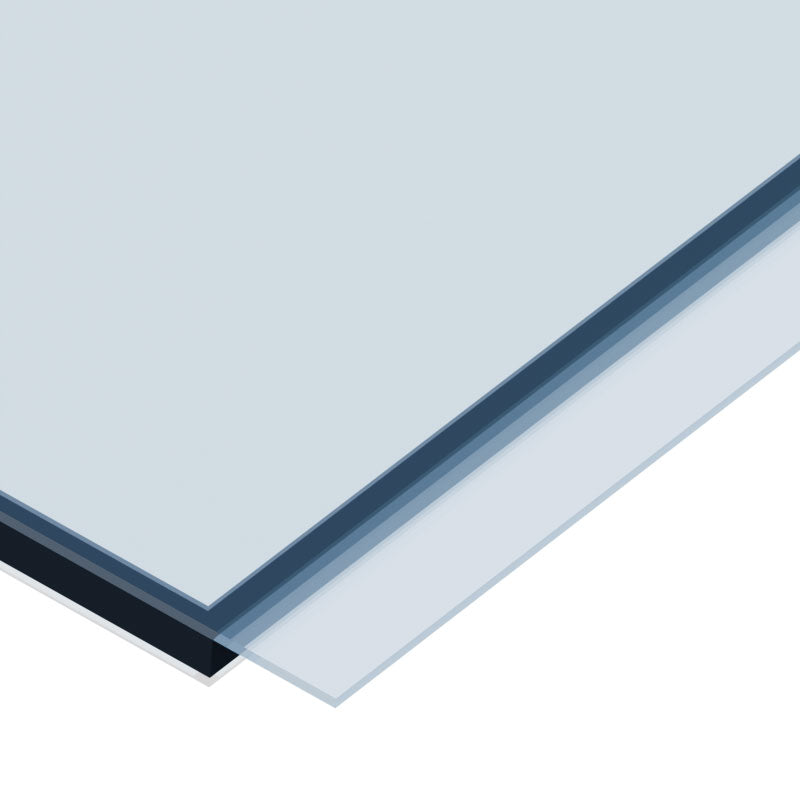

TuffX Ambi-SunShade Blue/Low-E 1.0u Solar Control Double-Glazed Glass Unit

Top-performing blue-tinted double-glazed unit that reflects up to 82% of solar energy and offers increased glare reduction. Toughened, self-cleaning conservatory roof glass providing exceptional 1.0 u-Value whilst limiting light transmittance to 50%. Part of the TuffX Ambience range, Ambi-Ambi-SunShade Blue/Low-E 1.0u maintains the internal temperature of a room, and prevents the uncomfortable and damaging affects of excessive ultraviolet light.

A favourite glass for conservatories with a south facing aspect.

- Stunning blue tint with high glare reduction

- High 82% heat reflection prevent excessive heat build-up

- Low-E coating increases comfort and reduces costs

- Argon gas improves thermal performance

- Made from toughened safety glass

- Easy maintenance self-cleaning glass

- Warm edge spacer bars prevent heat transfer on edges

- Arrissed edges for safer handling

Ambi-Sunshade/Low-E Double-Glazed Glass Unit (1u)

SKU: TUF-2312-1015

MPN:

AMBSSB1.00

10+ in stock

Couldn't load pickup availability

Special Options

How to Order

Ordering double-glazed and triple-glazed units doesn’t need to be daunting. That’s why we break down the main considerations, Performance Needs, Size Requirements, and Additional Options.and provide a little explanation to help you to make better choices.

Take a look at the following Technical Information, and Things to Ask Yourself, for a better understanding of the options. See the FAQ at the bottom of the page for more answers.

Technical Information

Ambi-SunShade Blue Range Comparison Table

| SunShade/Low-E 0.7u | SunShade/Low-E 1.0u | SunShade/Low-E 1.2u | SunShade/Clear 2.7u | SunShade/Satin (Privacy) 2.7u | |

|---|---|---|---|---|---|

| u-Value | 0.7 | 1 | 1.2 | 2.7 | 2.7 |

| Composition | SunShade/Low-E | SunShade/Low-E | SunShade/Low-E | SunShade/Clear | SunShade/Satin (Privacy) |

| Solar Heat Reflection | 84% | 82% | 77% | 77% | - |

| Light Transmission | 24% | 50% | 27% | 27% | - |

| Low-E | Y | Y | Y | N | N |

| Argon | Y | Y | Y | N | N |

| Glazing | Triple | Double | Double | Double | Double |

| Thickness | 36mm | 20mm, 24mm, 28mm | 20mm, 24mm, 28mm | 20mm, 24mm, 28mm | 20mm, 24mm, 28mm |

| Max. Length | 3210mm | 3210mm | 4000mm | 4000mm | 3210mm |

| Self-Cleaning | Y | Y | Y | Y | Y |

Specification

| Specification | Detail |

|---|---|

| Spacer Bar | Black warm edge spacer bar. Thickness 10-20mm in 2mm increments. |

| Edgework | All edges are arrised (not fully ground) for safe handling. |

| Unit Thickness | 20mm, 24mm, 28mm, 36mm (Triple-glazed) |

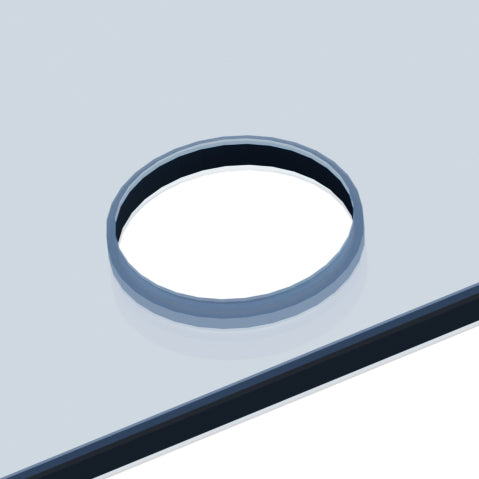

| Fan Hole Cutout | Cutout size and position must meet certain conditions to maintain the integrity of the unit. If choices compromise this, we will contact to discuss. |

| Colour Match | Exact colour match to existing units cannot be guaranteed, as the float glass used in the manufacture of units can be sourced from different manufacturers. |

| Guarantee | 10-Years |

Manufacturing Limits

| Specification | Detail |

|---|---|

| Min. Width | 300mm |

| Max. Width | 900mm |

| Min. Length | 300mm |

| Max. Length | 3210mm |

| Max. Area | 2.9m2 |

| Special Resuest | Units can be manufactured upto 1500mm x 4000mm. Contact to discuss. |

Manufacturing Tolerances

| Specification | Value |

|---|---|

| Width and Length | +1mm / -2mm |

| Thickness | ±1.5mm |

| Thickness (Float Glass) | ±2mm for 4-6mm panes, ±43mm for 8-12mm panes, and ±1mm for 15-19mm. |

| Stepped Edges | ±3mm for overhangs up to 100mm, and ±4mm for up to 250mm. |

Standards & Compliance

| Standard | Attainment |

|---|---|

| Accreditation | ISO9001:2015 |

| Thermally toughened soda lime silicate safety glass | EN 12150 1-2 |

| Hermetically sealed insulated glass units | EN 1279 Part 1, 5 & 6 |

| Laminated glass and laminated safety glass | EN12543 1-6 |

| Heat Strengthened Glass | EN 1863 -1 |

| Heatsoaked thermally toughened soda lime silicate safety glass | EN14179 1-2 |

| Float glass thickness standard | EN 572-2 |

To compare characteristics of the Ambi-Aqua products against others, view the Ambience Conservatory Roof Glass range.

Things to Ask Yourself

Note: Satin units, with their high 2.2 u-Value, fall outside the requirements of Building Regulations. However, satin can be used internally, or in a conservatory that is either unheated, or can be closed off from the main house by doors.

Delivering Your Glass

We are able to deliver insulated sealed units of glass to most mainland postcodes, but quieter and more rural destinations may have a longer time in transit time. Expected delivery date shall be advised in our order confirmation back to you.

-

Receiving Delivery

- Drivers will help offload from the vehicle, but the recipient is responsible thereon.

- At least one person is required on site to receive delivery. For larger units, we recommend two able bodied people.

- Pads or shrink-wrapping may be applied to protect units during transit.

- Check carefully to ensure you have all units, and that the labels describe the expected size and specification.

- We store and handle glass with care, but edges and corners are vulnerable, so check for damage, and inform the driver if you spot any flaws.

- A redelivery cost will be charge if unable to receive delivery on agreed day.

-

Storing and Handling

- Units are supplied with arrissed edges, but glass handling gloves should always be worn to further reduce likelihood of cuts, and slippage.

- Leave any pad or shrink-wrap protection in place until installation.

- Store in a clean, dry, ventilated space, away from direct sunlight and heat sources.

- Do not lay glass horizontally. Stand on edge between 3° and 6° from vertical.

- Prevent bowing, by ensuring that the back of glass is supported.

- To avoid staining, separate and dry thoroughly if moisture is spotted between stacked units.

- Double-glazed units weight 20 kg/m2 with 4mm glass, and 30 kg/m2 with 6mm glass. Triple-glazing adds an extra 50% to these respective figures.

FAQs

Can we supply triangles and other shaped units?

Yes! We can supply sealed double-glazed and triple-glazed units to triangular

shapes, and more. We intend to add the ability to order shaped units to the

website, but until then, please email us at sales@trulypvc.com, or call 0161 339 4982.

Can we supply sealed double-glazed units with cutouts?

Yes, we can supply units with cutout notches, and circular holes known as Fan Holes. Fan Hole size and position can be specified above, but you will need to contact us to discuss notches.

What is u-Value?

u-Value describes how well a glass unit resists heat transfer. The lower the value, the less heat transfers through the unit, and the more efficient the insulation. Building Regulations require that windows on

a new build have a u-Value of no more than 1.2, and replacement windows on

existing no more than 1.4.

What is Low-E glass?

Low-E (low-emissivity) glass units have a microscopic heat reflecting coating applied to a surface in the cavity, normally on the inner pane. It can help maintain a comfortable temperature by preventing heat loss during cold spells, and excessive heat gain during warm ones. Low-E can also protect furniture from fading, by reducing ultraviolet (UV) light.

What is Argon glass?

Argon is a non-toxic gas that is often used in the cavity of sealed units. It’s colourless, odourless, and denser than air, which slows convection inside the unit, and so improves thermal performance and energy efficiency.

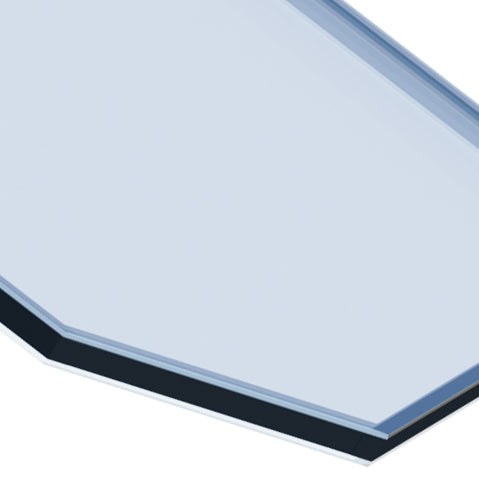

What are stepped edges?

Sealed insulated glass units can be supplied with stepped edges, that have the outside pane extend beyond the inner panes. Steps provide attractive drip edges that can take rainwater away from the seal, and allow the unit to be seated soundly in certain frames.

How does self-cleaning glass work?

The outside surface of self-cleaning glass has a coating that

reacts with the suns UV (Ultraviolet) rays to trigger a process that loosens

and breaks down dirt particles. The coating attracts water and encourages it to

spread and form a thin film, instead of forming droplets. This film sheets away

quickly and dries without leaving unsightly drying spots. Less dirt and grime

is left behind, resulting in glass that stays cleaner for longer.

What are warm edge spacer bars?

Warm edge spacer bars sit between panes of glass around the perimeter of a sealed unit. It prevents the release of the inert gas within the cavity of a unit. Made from a low thermally conductive material, it also acts as a thermal break to prevent heat transfer at the edges of the window. Warm edge spacer bars improve thermal efficiency, lower heating bills, and reduce carbon emissions.

What are arrissed edges?

Arrissing is the process of removing unevenness and sharp edges. A glass unit with arrissed edges is much safer to handle, and less likely to cause cuts.

What is toughened safety glass?

Toughened safety glass is processed by subjecting panels of glass that are edge worked to a heating and cooling treatment whereby high compressive stresses are set up at the surfaces with balancing tensile stresses in the centre. The high compressive surface stresses that remain are what gives its increased strength.